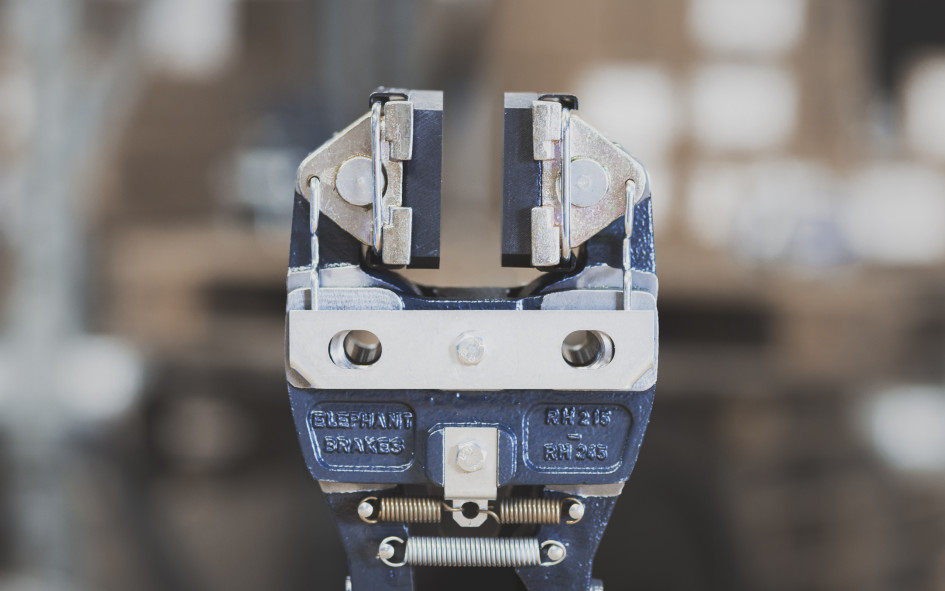

Rietschoten Elephant Brakes

For more than half a century, this medium-sized company based in Hanover has been developing, producing, and selling powerful and robust industrial disc brakes for extreme applications.

Headquarters

Hanover, Germany

Industry

Industrial brake systems

Products

Hydraulic, pneumatic or springoperated disc brakes

Applications

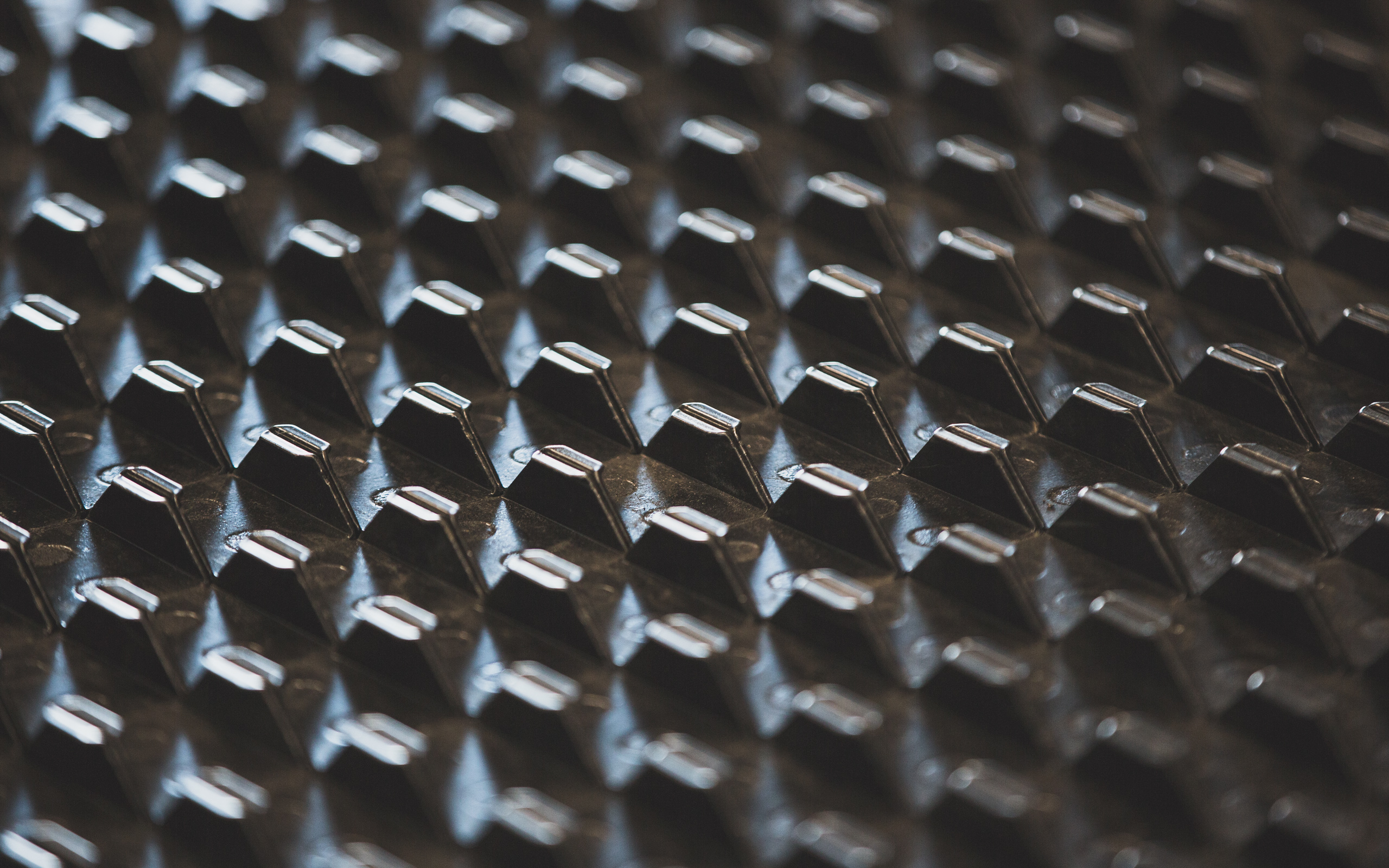

Ultra-rugged disc brakes for conveyor systems used in mining, brakes for amusement rides or lifts in skyscrapers, bespoke products for shaft locking devices in shipbuilding, temperature resistant brakes for the steel industry, extremely powerful disc brakes for large fans in power plants, highperformance brakes made of nickel-chromium alloy for the offshore industry, special

Expertise

Bespoke brake systems for extreme conditions

Since

1961

Internet

www.rietschoten.de

Portrait

Distributor turns into developer

Over the past five decades, Rietschoten Elephant Brakes has evolved from being a pure distributor to an important producer of high-performance and bespoke calliper disc brakes. The individually assembled products guarantee the secure deceleration of, for example, the lifts in the 492-meter SWFC Tower in Shanghai or the Freedom Tower in New York. In its ships, the Royal Navy also uses brake systems designed and produced by the experts from Hanover. In offshore wind farms, robust rotor brakes withstand the effects of salt water and storms.

This pioneer in the niche industrial disc brake market has grown to be the market leader in the field of custom-made products with specific performance characteristics. The technology has developed rapidly over the years, and the possible industrial applications are virtually unlimited today. Now, building on its comprehensive modular system for many standard applications, Rietschoten Elephant Brakes can meet customer needs quickly and efficiently. These range from special solutions to meet extreme requirements to unique products for customer-specific applications. Other business areas include maintenance, repairs, and the commissioning of complete braking systems.

Advancing future growth, the Hanover-based company is increasing its investment in proprietary brake systems and the expansion into international markets. Rietschoten Elephant Brakes has been part of the Obermark group of companies since 2011.

Application

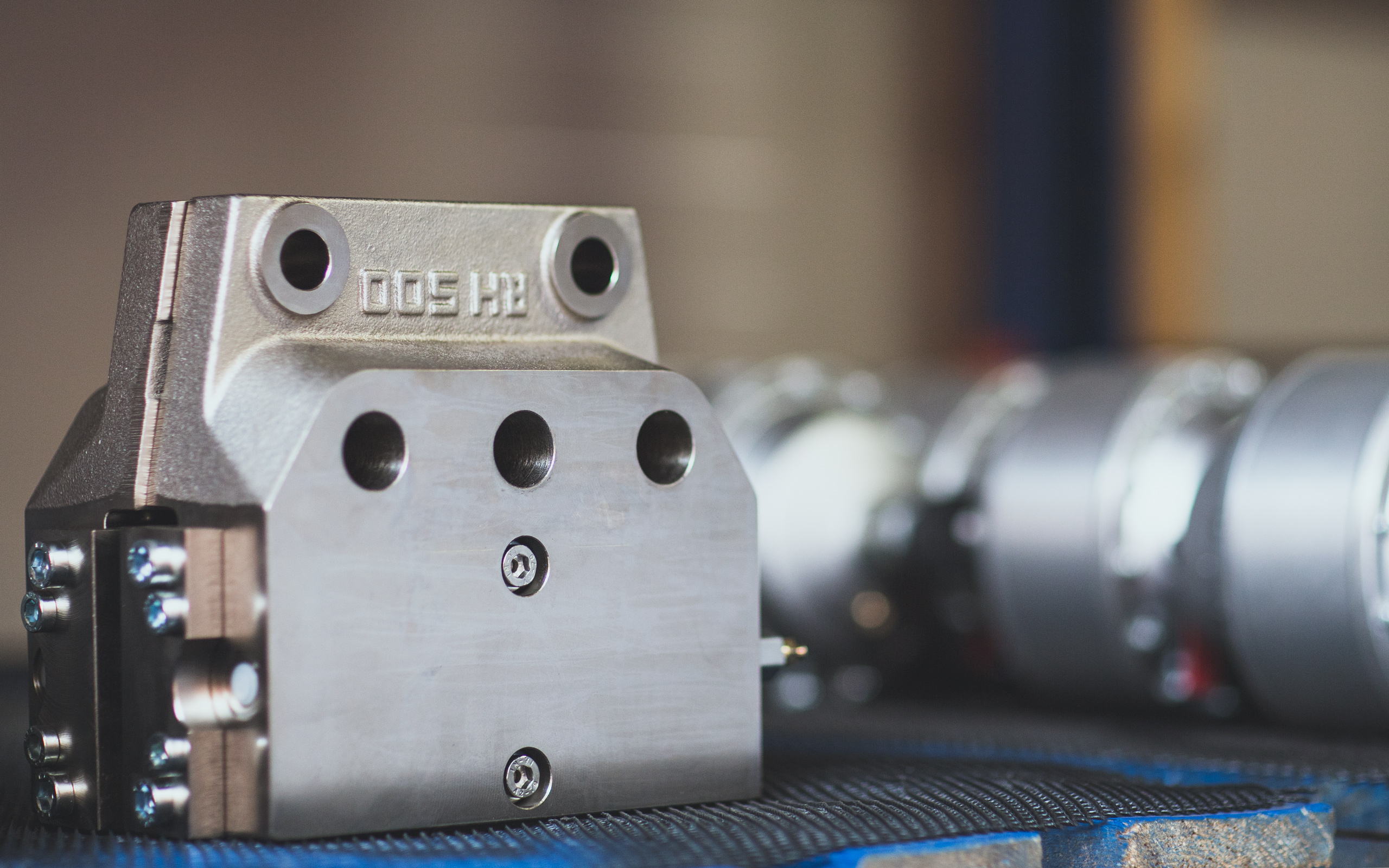

Full power

It not only takes nautical skills but also ambitious brake technology to gently decelerate a propeller of six and a half meters in diameter and rotating at a speed of 80 revolutions per minute. By the end of 2017, the Royal Navy will have built four new MARS tankers (supply vessels with a length of 200 meters) which are equipped with modern hybrid propulsion technology. In 2014, the Royal Navy contracted Rietschoten Elephant Brakes to deliver the complete brake systems for all four ships, making it the largest single order in company history.

In addition to the brake system and blocking unit, the order includes the turning device. It allows for the electric rotation of the entire shaft line as soon as the command “Full power in reverse!” is heard.

Markets

Focus on Europe

With its brake systems, Rietschoten Elephant Brakes initially grew in Germany. In its home market, the company is renowned for quality and service. In addition to further strengthening its presence in Germany, Rietschoten Elephant Brakes is now also focused on the broader European market.

Insights

Every company and each employee are unique and have a distinct history. The following texts offer an impression of the motivation, perspective and convictions of the people behind the stories.