“The material has to withstand freezing temperatures as well as heat of up to 200 degrees Celsius.”Jana Zemke

Secret recipes

Investing in new products is worthwhile even for a medium-sized company. Jana Zemke tinkers with extra robust adhesives and materials at inotec Barcode Security. This creates unique products that contribute to the company’s high profitability.

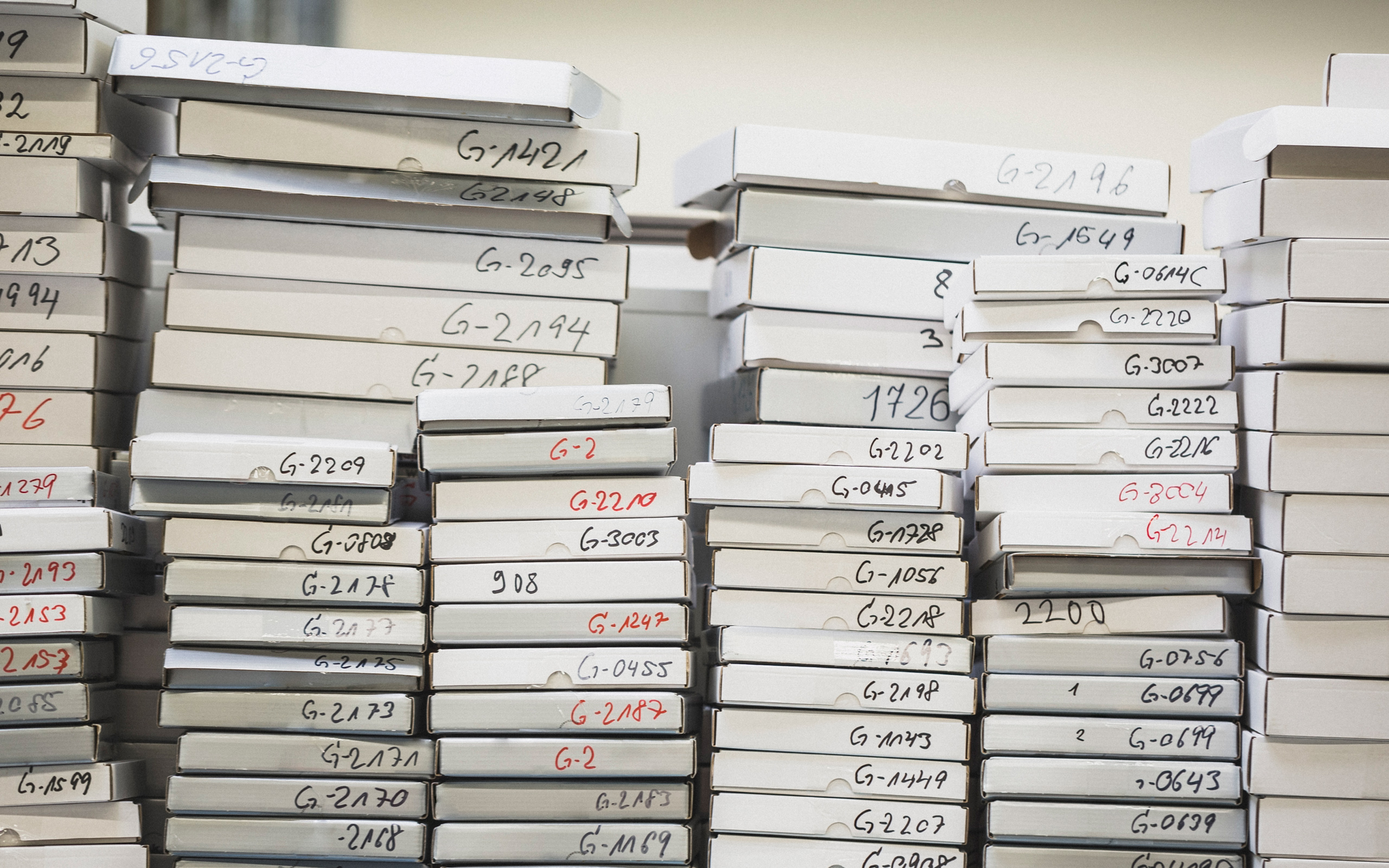

The exact formulations of the varnishes, adhesives and other materials are well kept secrets at inotec Barcode Security GmbH. They originate in the label competence centre: a laboratory, directly on top of the production floor, where Jana Zemke is testing small samples of a substantial variety of materials.

Right at this moment, she is investigating a solution for a RFID application on a metal container. “An RFID chip cannot simply be mounted on metal, since the direct contact disrupts scanning.” The metal interferes with the radio waves. Jana Zemke is working on a foam, applied between chip and mounting surface, that restores the desired functionality. “This is not trivial, since the material has to withstand freezing temperatures as well as heat of up to 200 degrees Celsius.” In addition, resistance to acids is important, and the adhesive must be reliable for several years under these conditions.

High customer added value through special applications

Very few producers are able to develop high quality products for equally specific requirements. Once invented, they can be marketed correspondingly well.

A number of prototypes are currently waiting on the lab's counter. For example, see-through foil scraps bathe in small bowls containing acetic acid, water and other chemicals. “We are testing different adhesives and materials that enable the labels to reliably adhere to clothes without leaving any residue,” says Jana Zemke. These stickers are used in the clothing industry, for example for size markings. Another trial relates to dyes which do not fade despite their exposure to a number of environmental factors.

“We are testing different adhesives and materials

that allow labels to reliably stay attached to clothes without leaving any residue.”

For other materials, in turn, there is the additional requirement that they must consist of three individual peelable layers. Still other labels are to be secured with a strap, replacing the glue.

Last hurdle: weathering locker

Based on these product-related challenges a number of materials have been developed over the years at inotec Barcode Security that today can be used for unique products, their sturdiness unmatched by competitors. For a wide range of customer applications, the company works with different resins, polymers, polycarbonates, metals and ceramics that are repeatedly mixed and remixed almost as if in an alchemist's kitchen. As soon as Jana Zemke finds a promising combination, it is initially placed in the weathering locker. This is a device the size of a furnace that simulates the effects of years of exposure to weather conditions such as rain and wind – all within a few days. To top it all off, the sample is also tested for its resistance to cold in the freezing chamber with temperatures of as low as minus 85 degrees Celsius.

When in use, the inconspicuous barcode label rarely betrays these efforts. They become evident only when even after years of service these products still look like new and continue to function as required.